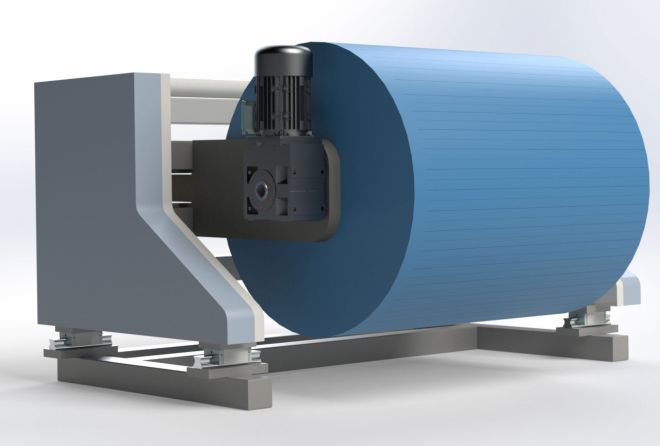

Servo-controlled winding machines

Highly precise, fast and reliable

Our servo-driven high-performance unwinding, rewinding and re-reeling machines enable precise converting of a wide variety of roll materials, such as paper, films, nonwovens, fabrics and textiles.

Together with our customers, we develop individual and customised solutions and thus ensure a smooth flow in the machine finishing process. The spectrum of our configurations ranges from fully automatic reel change systems to ready-made reel take-off systems. Depending on the production requirements, individual components of our winding machines can be combined with each other if necessary.

Integrated control systems for maximum reliability

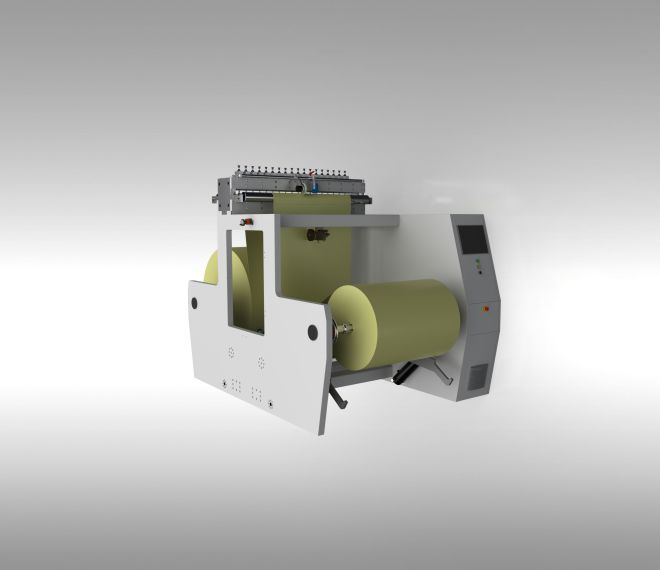

Depending on the requirements of the production line and in order to ensure a smooth production process, our winding machines are equipped with a wide variety of additional components. For example, on request, an integrated web edge control system provides automated correction of the unwinding direction and thus ensures precise winding of the processed product at the end of the production chain, even at high web speeds.

Based on our years of experience in mechanical engineering, we know that failures and interruptions within a production line are extremely costly. An integrated web tension control is therefore indispensable nowadays. This additional equipment can also be integrated into our machines on request and minimises the breaking of a material web to the utmost.

Our high-performance winding machines have a lifting device that makes inserting and removing the material rolls child's play. They also have highly sensitive diameter sensors that provide an overview of how much material is still on the roll at any time. This means that the time for changing the material roll can be determined precisely. Combined with our specially developed web splicing table, the time to change and splice a new roll of material is just 13 seconds.

All advantages at a glance

- Winding speed: up to 500m/min

- Roll diameter: up to 3000 mm

- Working width: up to 4000 mm

- Output: Servo motors

- Materials: Papers, foils, nonwovens, textiles, etc.

- Possible additional equipment: web edge control, web tension control, lifting device, diameter sensors, web splice table