Perforating and Foil Welding Systems

Thermal welding and perforating with highest precision

Foil Welding Systems

End products from a wide range of industries can only be manufactured by using thermal welding processes. These include, above all, various products from the packaging and medical industries. The production of bags, liquid packaging, but also medical products require the highest precision and the use of different welding processes. With our film sealing systems, we cover a whole range of sealing variants and thus find the right solution for every application:

- Welding with a welding roller for joining foils or bags

- Linear welding for straight-line sealing

- Overlap welding for joining individual film pieces

- Impulse welding for ideal welding process control

- Continuous welding with permanently heated sealing bars

- Pre-welding - for pre-treatment of thicker material

- Shape welding for the packaging and medical industries

- Longitudinal cut-off welding - ideal combination of welding and cutting process

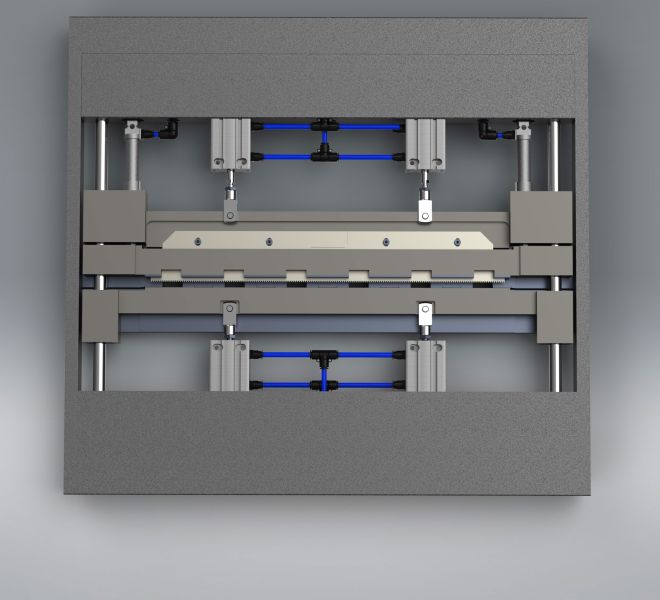

Perforating Systems

With perforation (or also called punching), the material to be processed is perforated at regular intervals so that the material can later be easily separated at this point. During this process, small webs remain, which still hold the material together. This process requires the highest precision.

Flomet Solutions specialises in the development of a wide range of perforation systems for different types of perforation. Our machines are designed for all types of punching processes, depending on the nature of the material to be processed:

- Perforating machines (small hole punches for perforating the material)

- Cross perforation (e.g. separation of a rubbish bag)

- Cold-needle perforation (paper sector)

- Hot-needle perforation (guarantees uniform perforation of the material)

- Hole-Punching machines

- Special perforating machines (longitudinal perforation, perforation to the web direction or slit perforation)